When creating packaging for your brand, there are many important decisions to make. One key factor is cardboard thickness, it plays a big role in making packaging durable and protective. This guide will help you understand cardboard thickness and how to choose the right one for your packaging needs.

What is cardboard thickness?

Cardboard thickness means how thick the cardboard is. Thicker cardboard is stronger and protects your product better. It is measured in millimeters or microns. A micrometer or calliper is the tool used to measure the cardboard thickness.

Why cardboard thickness matters?

Choosing the right thickness is important because:

- It keeps your products safe

- It handles shipping better

- It helps lower shipping costs

- It improves printing results

At first, all cardboard may look the same, but the thickness makes a big difference. Here’s why:

Protection of Contents

Cardboard thickness plays a big role in protecting the products inside the packaging. If you’re shipping fragile or breakable items, thicker cardboard gives extra padding and keeps things safe during transit. The right thickness keeps your products safe and your customers happy.

Shipping Durability

The thickness of the cardboard is important for how well a box holds up during shipping. We’ve all received a box that’s been damaged with tears and punctures. Shipment of boxes is a tough process, so choosing the right thickness ensures your packaging can stay secure without getting damaged.

Shipping Cost

Shipping costs are affected by the weight of the cardboard used. The thicker the cardboard, the heavier the box, which leads to higher shipping costs. Using thicker cardboard can increase transportation expenses. Understanding cardboard thickness helps you make better choices to keep shipping costs lower.

Enhancing Print Quality

For high-quality printing, the cardboard needs to be thick enough to handle the process. Thinner cardboard may not provide the best results for premium prints. If you want sharp, vibrant prints, it’s important to choose a thicker cardboard that supports high-end printing.

Cardboard Thickness Measurement Methods

There are different ways to measure cardboard thickness, including grams per square meter (GSM), the point system (PT), flute type, and board style. Each method has its way of suggesting the thickness, so understanding them helps you choose the right cardboard for your packaging needs. Here’s a detail of each method to help you make a decision:

Method 1. GSM (Grams per Square Meter)

Grams per square meter (GSM) is a common way to measure the weight and thickness of cardboard. It’s one of the most accurate methods, especially for materials like corrugated cardboard. Here’s a simple guide to help:

- 35 to 55 GSM: Typically used for newspapers

- 90 to 100 GSM: Common for printer paper

- 120 to 140 GSM: Used for posters

- 210 to 300 GSM: Often found in brochures

- 350 to 400 GSM: Used for packaging

For strong and thick packaging, you’ll want cardboard with a GSM of 350 or more. A higher GSM doesn’t always mean the cardboard will be heavier. While GSM is an important factor, it’s just one of the elements that affect cardboard’s weight and strength.

Method 2. Point System (PT)

The point system (PT) is another way to measure the thickness of cardboard. In this system, each “point” equals 1/1000 of an inch. The thickness of cardboard can range from 8 points, which is very thin, to 16 points, which is much thicker. This method is often used to measure the thickness of paper and corrugated cardboard, helping you choose the right material for your packaging needs.

Method 3. Corrugated Flute Type

Another way to measure cardboard thickness is by the type of corrugated flute. The “flute” refers to the wavy layer of paper between the outer cardboard sheets. These flutes help make boxes stronger and better at protecting items. There are different flute sizes to choose from, each offering different levels of protection. Here are some of the common flute sizes:

- B flute: 3 millimeters thick (about 1/8”)

- E flute: 1.5 millimeters thick (about 1/16”)

Method 4. Corrugated Board Type

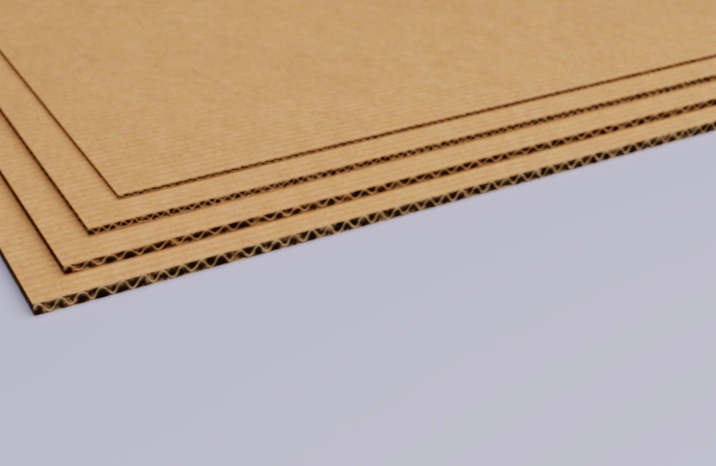

You can also determine cardboard thickness by the type of corrugated board. The layers of flutes and liners are put together in the cardboard. Most cardboard boxes are made from single wallboards, where two liners surround one fluted layer. There are other types of corrugated boards as well:

- Single Face Boards: Made of one liner and one fluted paper. These are less durable and are mostly used for inner packaging.

- Double Wallboards: Composed of three liners and two fluted papers. These offer more protection and are perfect for heavier or fragile items.

- Triple Wallboards: Made of four liners and three fluted papers. These are designed for heavy items like appliances and industrial equipment, offering maximum protection.

What is the best cardboard thickness for different products?

When choosing the right cardboard thickness, it’s important to think about what you’re packing and how it will be shipped. Here’s a simple guide to help you select the right thickness for your packaging:

Lightweight Items

For lightweight products like clothing or small accessories, you don’t need very thick cardboard. A thinner cardboard works just fine for protecting these items while keeping costs down.

- Material: Paperboard or Cardstock

- Recommended Thickness: 12 pt to 18 pt

Medium-Weight Items

Items like electronics or books need more protection, but still don’t require heavy-duty cardboard. A medium-thickness cardboard will work well to ensure that these products are safe during shipping and handling.

- Material: Paperboard or Cardstock

- Recommended Thickness: 20 pt to 24 pt

Heavy or Fragile Items

For heavy or fragile items like glassware and machinery parts, you need sturdy and thick cardboard to prevent any damage during transport. Thicker cardboard helps protect delicate products from bumps, drops, or rough handling.

- Material: Corrugated cardboard with single-wall or double-wall structure

- Recommended Thickness: Flute types like E-flute, B-flute, or C-flute for single-wall packaging, and BC-flute for double-wall packaging.

How to choose the best packaging?

There are a few points for choosing the best packaging:

- What type of product is inside

- How will the package be shipped

- Your budget for packaging

- The artwork design and printing you plan to use

- The packaging supplier you choose

Now that you know the basics of cardboard thickness and its measurement, let’s look at these points more closely to help you make the best choice for your packaging.

Step 1. Select the Right Fit for Your Items

It’s important that the packaging fits your product correctly. If your product is fragile, like glass or electronics, you’ll need thicker cardboard for extra protection.

Always choose packaging that matches the size of your product. For lighter, non-breakable items, a thinner option is good. Add custom inserts or dividers to keep your products safe and in place.

Step 2. Shipping Method

Choosing the right shipping method is as important as choosing the best packaging for your brand. Otherwise, your product may get damaged from rough handling during transit.

A thicker cardboard that can handle bumps, drops, and stacking. This helps your product arrive safely.

Step 3. Packaging Budget

Shipping cost depends on the weight and size of the items. Also, different thicknesses come at different costs.

Thicker cardboard is usually more expensive. So, choose the cardboard thickness according to your product weight and budget.

Step 4. Design Plan

If you want to add high-quality printing or bold graphics, a thicker cardboard is perfect because it has a smooth surface for printing.

Thin cardboard may not hold detailed designs well. For simple prints, a thinner sheet can work well.

Step 5. Work with a Packaging Expert

If you’re confused about what to pick, then get help from a packaging professional. They can guide you in choosing the right thickness and design based on your product and budget.

Final Words

CustomBoxWire is a custom packaging provider with years of industry experience. We offer a variety of packaging products that you can easily customize online to match your brand.

You get a fast 7-day turnaround, high-definition printing, and durable materials to ensure your packaging looks great and protects your products.